The RTMS is an industry–led, government-supported, voluntary, self-regulation scheme that encourages consignors, consignees and road transport operators to implement a management- systems standard with outcomes that contribute to preserving road infrastructure, improving road safety and improving productivity. It is based on a SABS national standard, SANS 1395-2019 and the audits are conducted by a SANAS-accredited RTMS certification body. This ensures that international certification audit processes are implemented hereby ensuring trust and credibility in the market.

RTMS certification involves a 2-stage audit process as per the ISO 17021 standard which is the international standard applicable to all certification bodies. The audits are based on a sample population of trip data, vehicle history, driver information, telematics data, policies and procedures.

JC Auditors have been conducting RTMS certification audits since 2007 and report that RTMS has achieved exceptional road safety performance improvements over the last 14 years, specifically the reduced accident (crash) rates of RTMS companies. RTMS, like other management system standards such as ISO 9001 and ISO 45001 is based on the concept of self-regulation. Oliver Naidoo, managing director of JC Auditors states that “the concept of self-regulation is the main initial hurdle for many companies. This requires a transport operation to implement a deliberate and structured mechanism of managing the related risks.”

Currently there are more than 300 RTMS-certified fleets representing almost 18 000 motorised vehicles and almost 23 000 trailers. Numerous case studies presented at RTMS workshops by certified operators indicate some of the benefits that have been observed. These include:

- Reduction in overloading and speeding incidents

- Reduction in breakdowns

- Reduction in crashes

- Reduction in fuel consumption

- Increase in fleet availability/reduction in downtime

- Improved driver skills e.g. reduction in harsh acceleration and braking

- Improved attitude and motivation of drivers

- Reduction in chronic illnesses in drivers

- Improved general health of drivers and a reduction in absenteeism

The RTMS can be viewed as a tool that can be used by transport operators, consignors and consignees to improve fleet management and sustainability as well as reduce logistics costs.

RTMS is a holistic tool that can be used by a transport operation to ensure that it operates in a safe, compliant, and professional manner. The benefits of RTMS are receiving increasingly recognition by various corporate entities, with some of whom include RTMS as a prerequisite for contracts.

The last public RTMS workshop (pre Covid) was hosted by Coca Cola Beverages SA.

Broad smiles all around from companies who had recently received RTMS certification at this function.

L-R Mookho Morienyane (SANAS), Jonathan Richardson (CCBSA), Phindile Sibanyoni (TASA),

Kamogelo Rapitso (SABS), Adjei Ndanganeni (CCBSA), Byron Ah Tow (Air Products SA), Paul Nordengen (CSIR), Zinhle Nkosi (Skhwama Logistics), Adrian van Tonder (RTMS NPC), Motsamai Mohapi (Babcock Plant Hire) Kathy Bell (Standard Bank), Mbhekeni Malinga (Skhwama Logistics), Ndimakazi Mankomo (Babcock Plant Hire) Elvis Shabangu (Khanyi Ilanga), Oliver Naidoo (JC Auditors), Zamani Thwala (TASA)

Front David Nyathi (Air Products SA), Simphiwe Khoza (BR Khoza Carriers), Mauritz Bam (Khany Ilanga)

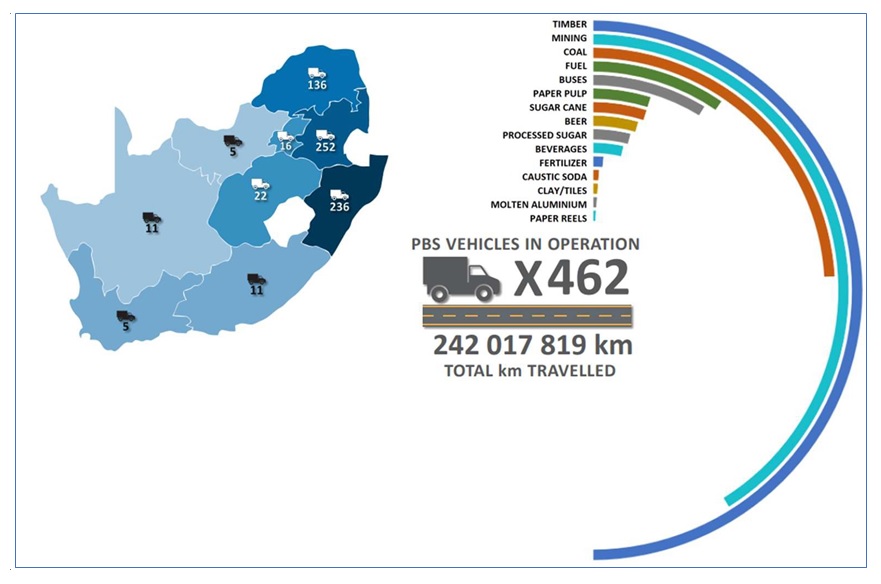

The Smart Truck or Performance-Based Standards project for heavy vehicles is currently being run as a pilot project in South Africa to evaluate the potential benefits of using the PBS approach for the design and operation of heavy vehicle. South Africa was the fourth country in the world to implement the PBS approach for heavy vehicles. RTMS-certification (to ensure a minimum standard of fleet management) is required for a transport operator to participate in the PBS project. The PBS approach allows for higher capacity vehicles (longer and or heavier) to operate on pre-approved dedicated routes. It is thus ideally suited for primary distribution road freight transport operations. As of December 2020, there were 462 PBS vehicles operating in various provinces and sectors as indicated in the following info-graphic:

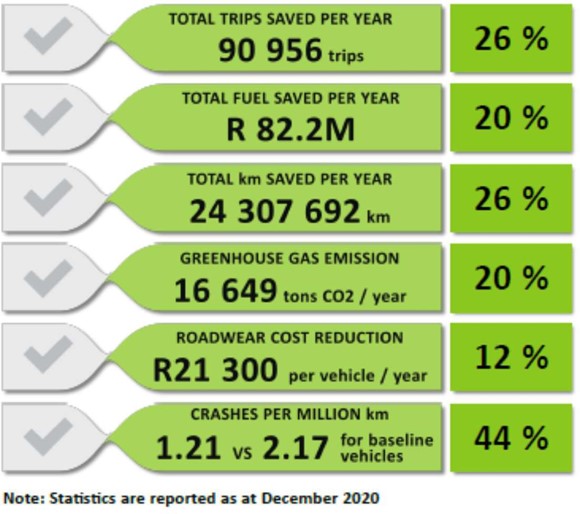

Measured benefits include reduced roar wear, reduction in vehicle trips, lower fuel consumption and emissions per tonne.km and a significant reduction in crashes as indicated in the following info-graphic:

The PBS (Smart Truck) pilot project has had a significant impact on logistics cost, emissions, infrastructure protection and improved safety. The PBS approach has been implemented in a few countries including Australia, New Zealand and Canada, and shown to improve heavy vehicle safety and productivity whilst also reducing the impact the vehicles have on the road infrastructure and the environment. It makes provision for an innovative and efficient road freight solution, improving competitiveness and making a positive impact on the economy.

The PBS (Smart Truck) evaluation report is currently being reviewed by the National Department of Transport who will decide on the future of the PBS project.